Yamato

Another layer of checks to your processing and packaging line

Coming in the processing line after metal detection and checkweighing, an X-Ray machine provides an additional deep visual check in real time for foreign bodies in your packaged products and automated rejection.

The combination of the checkweighers and metal detectors with an X-Ray system are flexible and are suitable for a variety of applications. X-ray technology delivers sensitive, fast and sophisticated detection.

You must appoint a Radiation Protection Supervisor (RPS) to ensure you comply with ionising radiations regulations. We can train your appointed RPS. You will also need to engage an external independent Radiation Protection Advisor (RPA) to support your supervisor. We can also recommend RPAs.

X-Ray Combi Systems

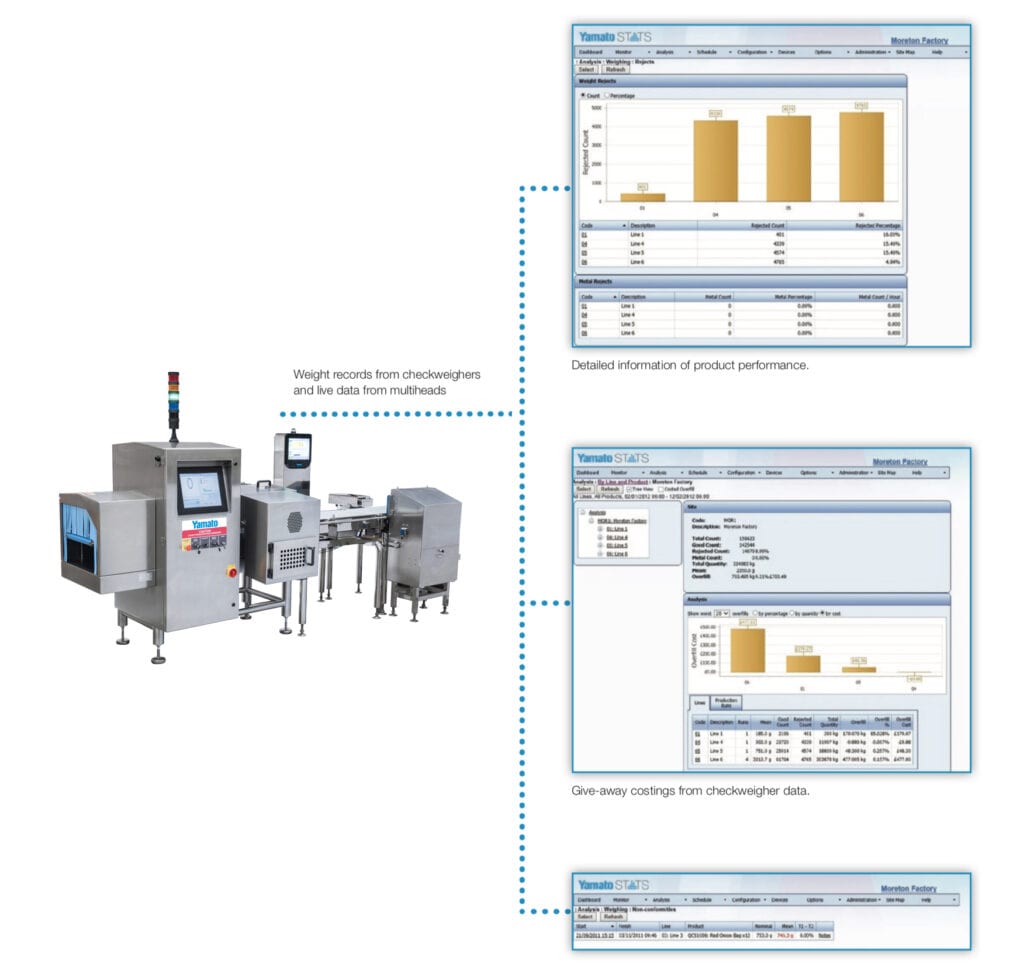

Weight and yield information from the multihead weighers and checkweighers, audit records from the metal detectors and performance data from the complete line, are all collected in real time to give the production and technical managers the tools to reduce costs and ensure compliance.

We’re happy to help. Call our team directly or request a callback and we’ll get right back to you.

Call us today on 01442 217384 for a no obligation consultation

Please enter your email address below and the selected download sheet will be emailed to you.